Wonderful Tips About How To Clean Up Pcbs

Place polarity indicators for power inputs, including.

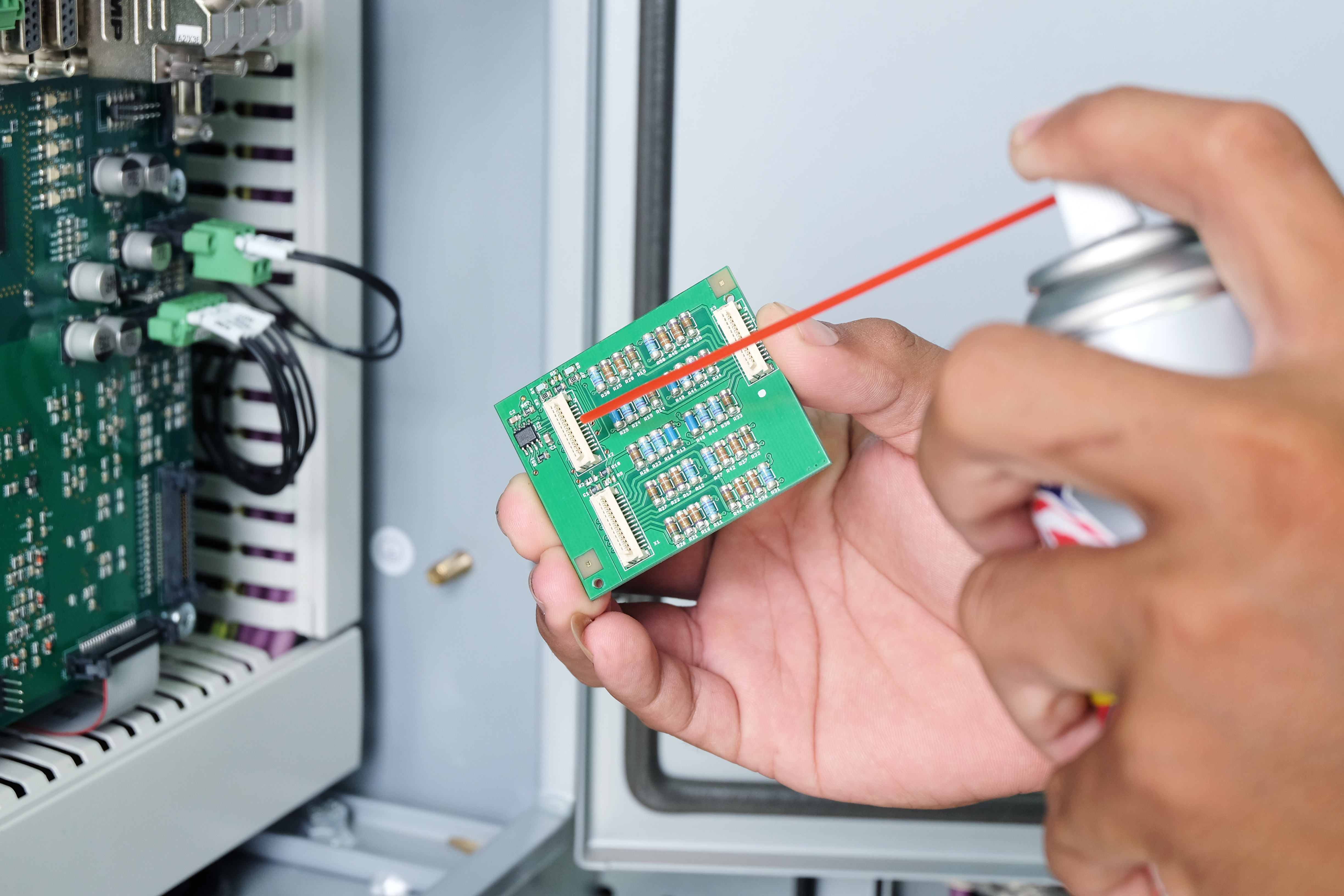

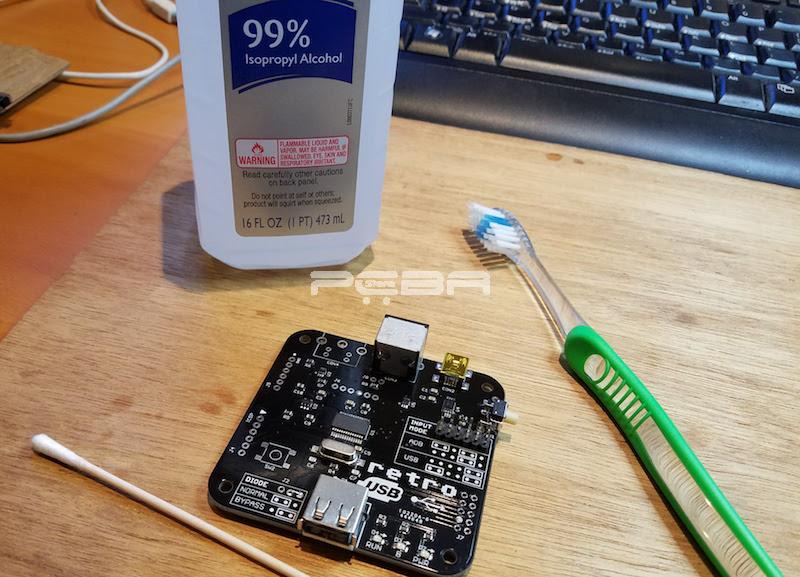

How to clean up pcbs. Industry standard pcb cleaning processes: Making the flux removal your success rate of cleaning the soldering residues from the electrical components. The steps of baking soda for pcb assembly cleaning are as follows.

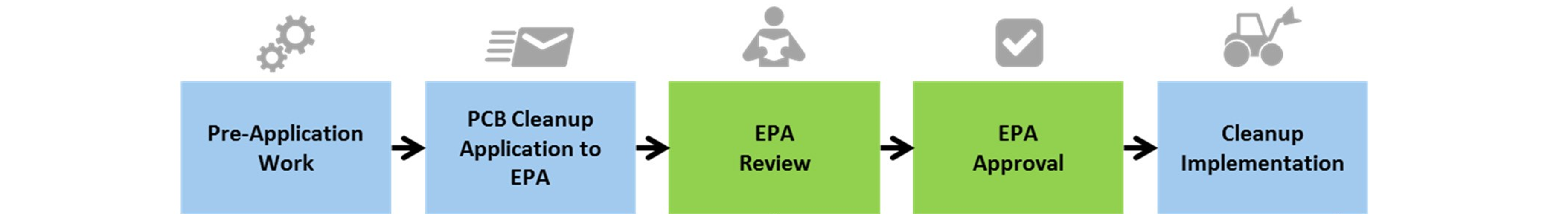

Demineralized water can be used as an alternative. (v) soil contaminated by the spill will be decontaminated to 10 ppm pcbs by weight provided that soil is excavated to a minimum depth of 10 inches. With this step, you will be able to access all the corroded parts of the circuit board.

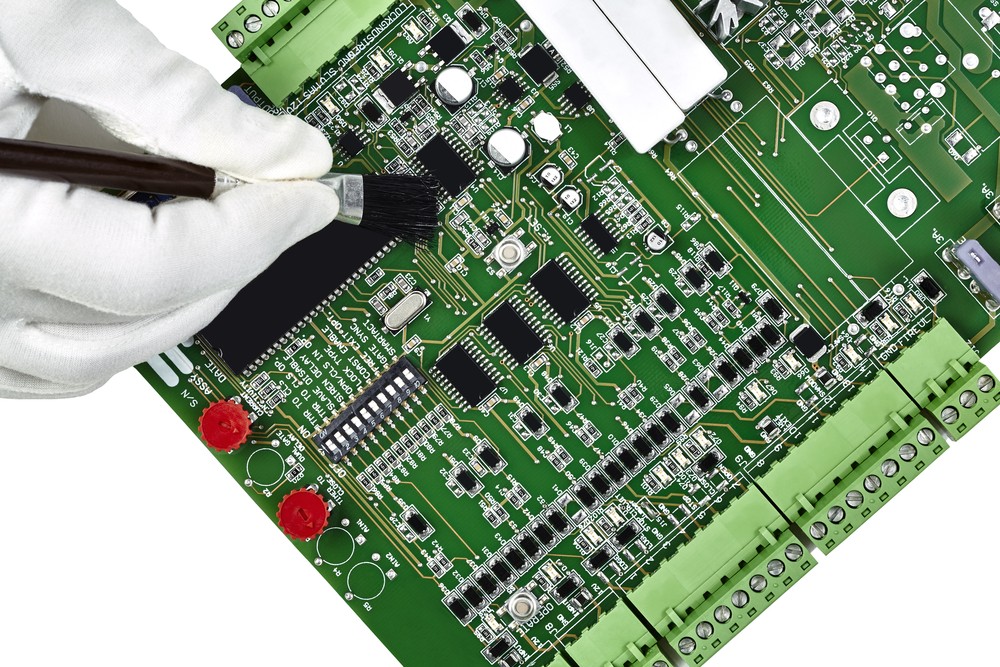

Be sure to remove any. Use a quarter cup of baking soda and a small amount of water to make a cleaning solution until the solution. Check components have polarity indicators applied in the footprints, pin 1 indicators, and outlines that do not fall beneath component bodies.

Manual cleaning the challenge of cleaning complexity as technological. You can make note of the pcb design configuration to. The excavated soil will be replaced with.

To provide regulatory information to the regulated community (those using, storing, or disposing of pcbs), and to provide risk/background information to those researching pcbs. The process includes the following steps: Cleaning a pcb with a solvent like ipa should only be done in a well vented environment, ideally under a fume hood.

Clean making use of distilled water and baking soda. Brush the board gently to avoid the breaking of the solder.